There are usually three heat treatment methods for martensitic stainless steel: (high temperature tempering or complete annealing), quenching and tempering (quenching and high temperature tempering), and quenching-low temperature tempering.

These heat treatment processes are discussed separately below. Martensitic stainless steel will form martensite due to air cooling after rolling and forging. Therefore, its rolling materials and forgings have high hardness and are not suitable for cutting, and must be softened before machining. There are two types of softening treatment methods: high temperature tempering and full annealing.

High temperature tempering is to heat the steel or forging to 680-780qC, keep it for 2-4h, and then air-cool it out of the furnace to transform martensite into tempered sorbite. The hardness of 1Cr13 steel can be reduced to that of HB190-2002Cr13 - 4Cr13 steel. Can be reduced to HB200- 2300.

Complete annealing: It is to heat the steel or forging to 840-900℃ (commonly used 860℃), keep it for 2-4h, and cool it with the furnace at an extremely slow cooling rate. The cooling rate for ICr13 steel is 20-25℃/h. The cooling rate of 2Cr13, 3Cr13, 4Cr13 steel is 15-20qC hydrazine. When the furnace is cooled to 600 ℃, it can be air-cooled. The metallographic structure after annealing is that granular carbides are distributed in the ferrite grains or carbide particles are distributed along the grain boundaries. The hardness of ICr13 and 2Cr13 steels can be reduced to below HB170 after annealing, and the hardness of 3Cr13 and 4Cr13 steels can be reduced to below HB217.

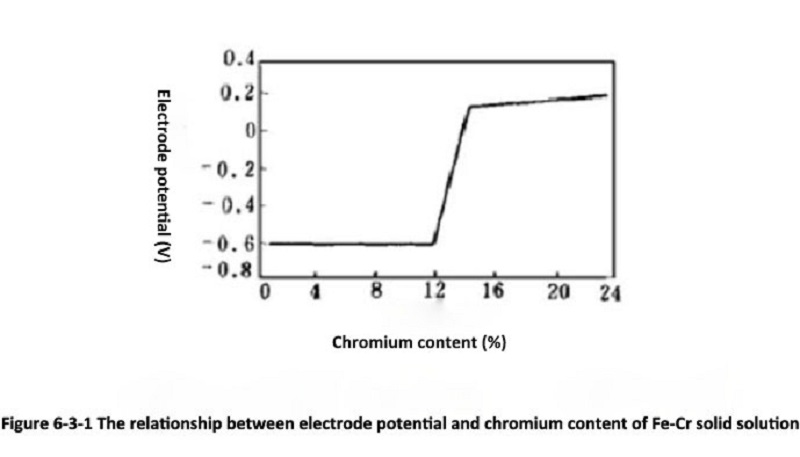

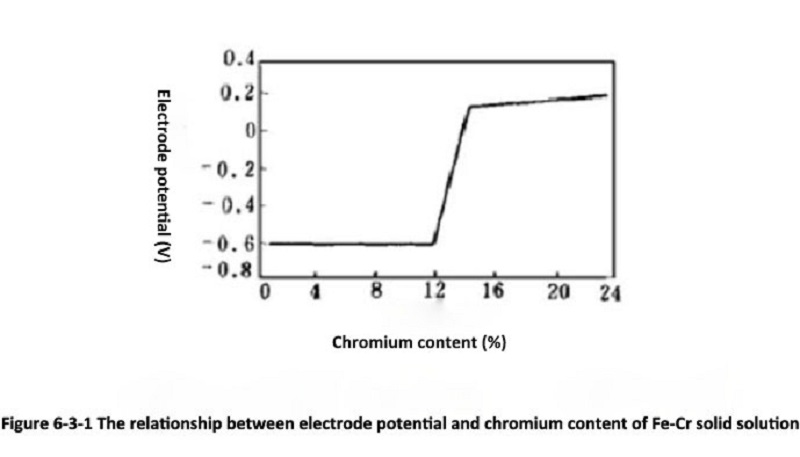

The corrosion resistance of Cr13 type stainless steel after annealing is low. This is especially true for steels with higher carbon content, because there is a large amount of chromium carbide in the annealed steel, which not only reduces the amount of solid solution chromium, but also the electrode potential of these chromium carbide particles is different from that of the steel matrix, forming many microbatteries. Accelerates the corrosion of steel. This condition can only be eliminated by quenching-tempering.

Cr13 stainless steel has 5 steel grades according to national standards. The main difference between them is the carbon content. In actual production, 1Cr13 to 3Cr13 are used the most, and other steel grades are used less. Their austenite isothermal transformation curves (C curves) are shown in the figure below.

It can be seen from the figure that their hardenability is very good. With the increase of carbon content, the C curve shifts to the right, and the hardenability is better. For example, the hardenability time of 1Cr13 steel (solid line) is 60s, while the hardenability time of 4Cr13 steel (dotted line) is increased to 300s. Due to their good hardenability, the martensitic structure can be obtained by cooling in air after high temperature heating. Therefore, Cr13 stainless steel is also called martensitic stainless steel.

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )